Laser Cutting Machine Applied In Elevator Industry

In recent years, with the improvement of national living standards, the rapid advancement of urbanization, and the rapid development of the real estate industry, the demand for elevators presents a rapid growth trend. It is reported that the elevator sales volume is expected to maintain a steady growth trend of 5%-10% in 2019-2020.

So, How do elevator sheet metal processing companies grasp the elevator market dividend?

At present, the elevator industry has entered a mature stage of development, industry competition is fierce, many manufacturers seek to upgrade technology, reduce costs and increase efficiency.

In the 1990s, elevator sheet metal processing plants basically adopted multi-station punch press to process plates, which required a large number of molds. Complicated mold design was time-consuming and laborious, and it required professional operators, resulting in expensive labor, long production cycle and high cost.

Elevator manufacturing involves a lot of sheet metal processing, which requires superior surface finish and high quality cross-section.

Punch cutting not only consumes the mold, but also produces the machined trace.

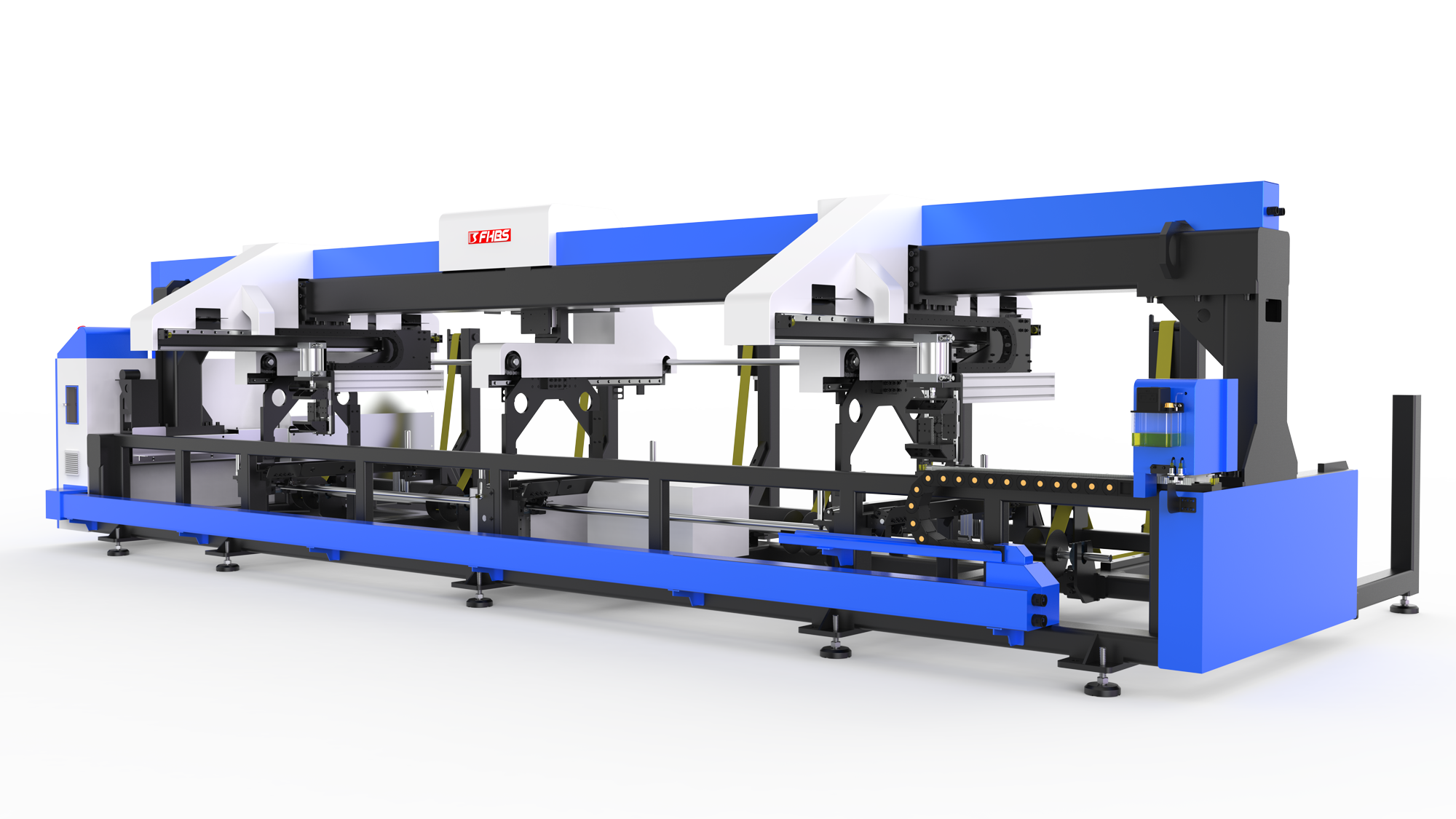

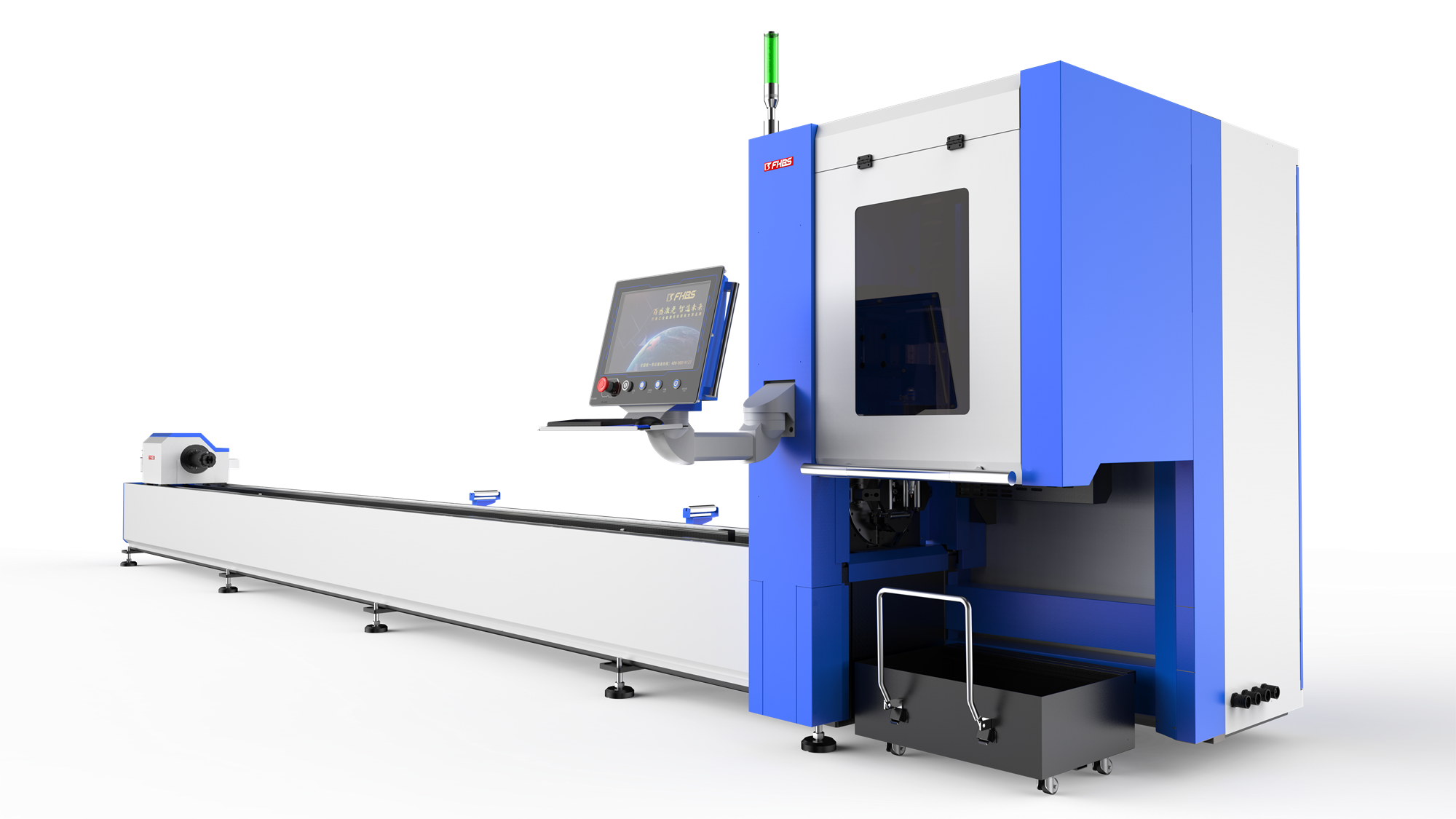

The laser cutting machine can realize non-contact processing, the cutting process does not damage the surface of the workpiece, and the speed is fast, the cut is smooth and flat, and generally does not need subsequent processing; the intelligent operating system can process any graphics, and large-format plates can be processed at one time without opening the mold.

At that time, many world-famous elevator manufacturers began to introduce laser cutting machines to improve the cutting quality and processing efficiency. However, due to the high price of early laser cutting machines, many small and medium-sized elevator sheet metal processing plants cannot afford the cost. It is one of the production advantages of big brand elevator manufacturers to use laser cutting machine.

With the rapid development of laser technology, low and medium power industrial laser cutting machines are widely supplied to the market. Domestic laser cutting machine manufacturers contend with each other, and equipment prices have dropped. Many elevator enterprises and accessories enterprises have purchased laser cutting machines.

Laser cutting machine can be used to process elevator door cladding, stainless steel or cold plate, elevator car, elevator chassis, door head components, protective fence, etc., and high-quality cutting of stainless steel plate, cold-rolled sheet, hot-rolled thick steel plate, I-beam, channel steel, angle steel and other materials.

The application of laser cutting machine in elevator sheet metal processing can greatly improve processing efficiency and quality, shorten the manufacturing cycle of new products, reduce labor intensity and processing costs, and create greater economic benefits for enterprises.