Laser Cutting Machine Applied In Oil-Pipe

In oil drilling operations, the production of sand from the oil layer will reduce the output of the oil well. The screen is an important tool for sand prevention and is widely used in oil and gas field completions. Slotted screens are cut into high-strength alloy steel casings with regularly distributed gaps. The slit cross-sections are mainly rectangular and trapezoidal. Slotted screen is the most commonly used sand control tool in mechanical sand control.

In the past, the price of the slit screen is expensive because it depends on foreign imports. The main use of slit screen seam milling cutter processing at that time. The milling cutter is made of high speed steel with poor hardness and slow cutting speed. The blade is thin and easy to be damaged in cutting. The width of the slotting is limited by the thickness of the cutting tool, so it is difficult to process the slotting less than 0.3mm. Moreover, the slotting of the milling cutter can only process the rectangular slotting screen, but not the trapezoidal slotting screen.

The appearance of grinding wheel cutting changed the situation that the screen was imported from abroad. However, the grinding wheel cutting seam is also difficult to be crossed by the milling cutter. The width of the slit is limited by the thickness of the grinding wheel, so it can only cut straight rectangular seam, and hard to cut the slit less than 0.3mm.

It was not until the emergence of laser cutting technology that technical difficulties in the processing of trapezoidal seams and ultra-fine seams were gradually solved.

Laser-cut screens use a focused ultra-dense laser beam to shine on the pipe, instantly melting or vaporizing the metal material. And then blow off the melt and residue by high pressure gas to achieve a slit cutting.

Compared with the traditional machining method, the laser cutting machine is a non-contact processing. The doesn’t have tool wear and cutting noise problems. it can produce trapezoidal seam and curved seam precisely and closely, the gap can reach 0.1mm, the width of the seam is regular, there is no slag in the seam, and there is no need for secondary processing.

It has the advantages of high processing precision, high processing efficiency and wide processing range. At present, the laser cutting machine has been widely accepted and put into production by the screen processing enterprises, which has realized the mass production of the slit screen well.

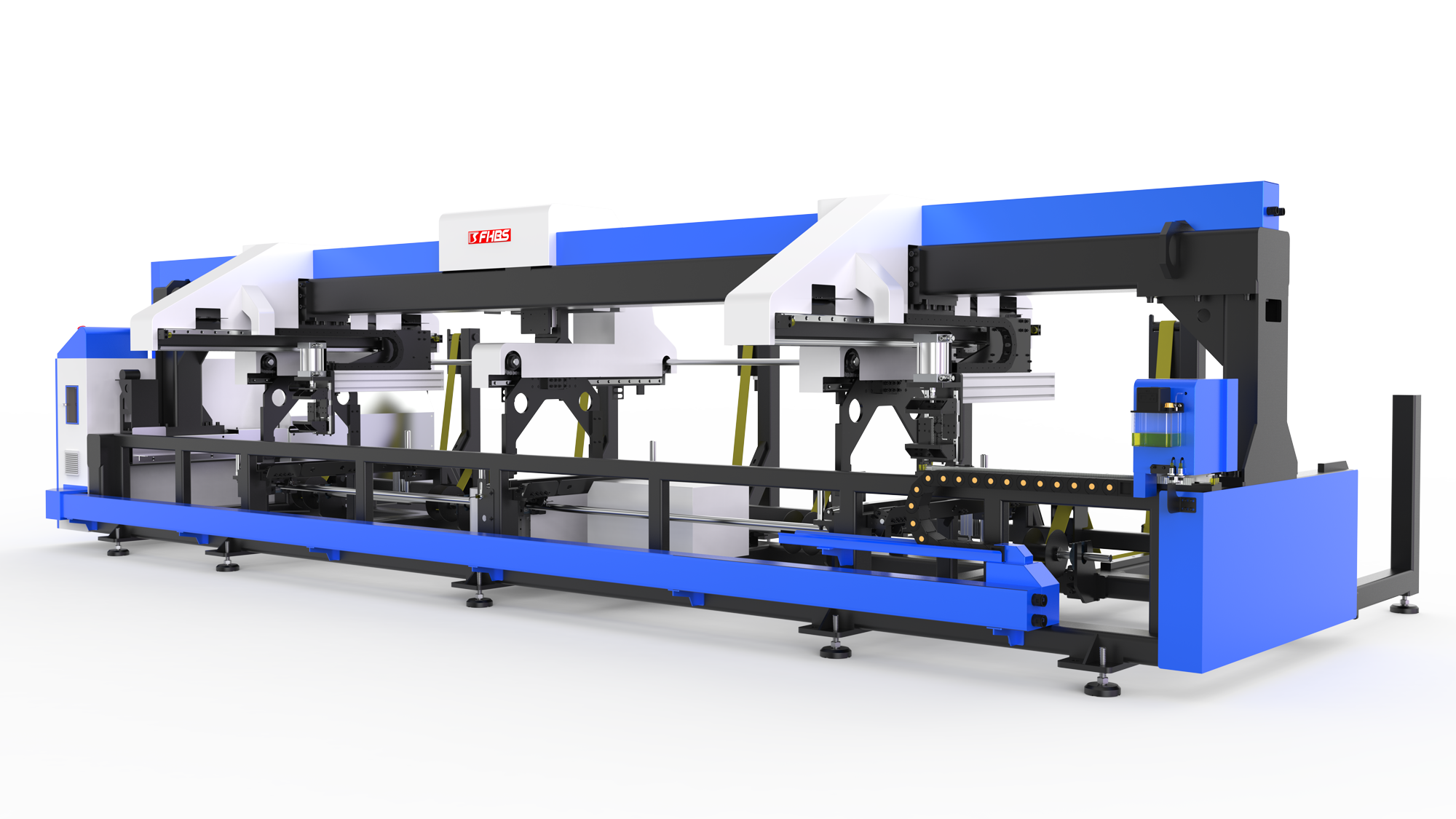

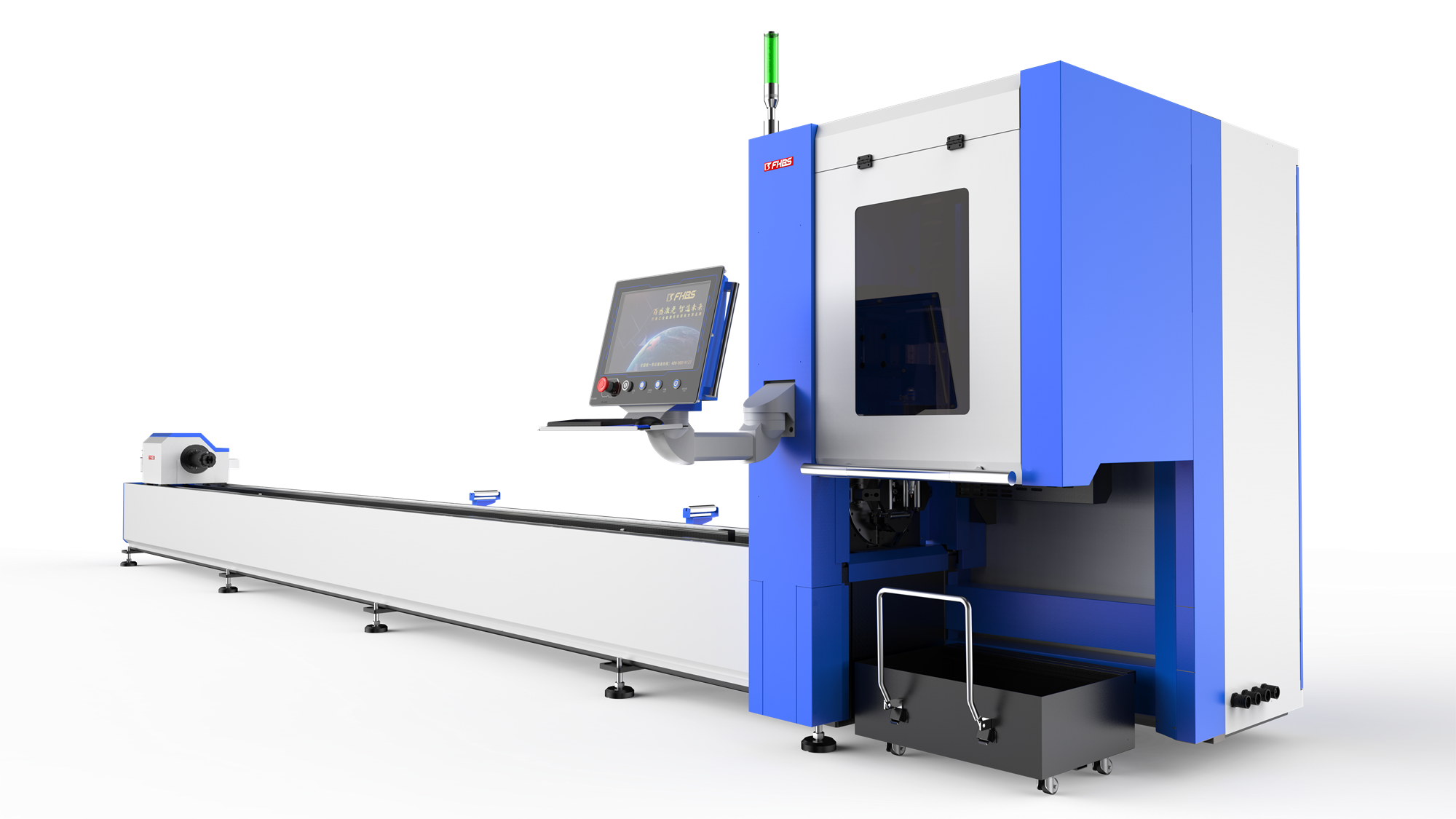

With the mature development of laser processing technology, the application of pipe laser cutting machine in oil- pipe has become increasingly popular. The sales of professional pipe laser cutting machine independently developed by BAISHENG Laser show explosive growth.

Baisheng professional tube laser cutting machine can stably cut stainless steel, carbon steel and other metal round tubes, square tubes, rectangular tubes, channel steel, I-beam, angle iron and special-shaped tubes. It supports pipe cutting, hole-opening, hollowing, oblique opening, butt through, butt joint with arc opening, 45-degree splicing cutting, etc. High quality cutting φ10-350mm round tube, □10-245mm square tube. Advanced cutting technology, clean and smooth cut surface of the workpiece, no burrs, no slag, and high pass rate. It can easily solve the problem of oil screen cutting.