What Are The Advantages Of Automatic Loading And Unloading Devices In Tube Laser Cutting Machines ?

Before the tube processing, the metal tube needs to be transported to the laser cutting machine worktable first. At present, the feeding methods of tube transportation mainly include manual handling, crane lifting and forklift.These three methods are low in automation, require high labor and time costs, and cannot maximize the production efficiency of the tube laser cutting machine.

Tube laser cutting machine can cut a large number of sheet metal workpiece for a long time each day. Continuous production can bring considerable economic benefits for manufacturers. Automatic laser loading and unloading system can shorten the overall loading and unloading time, and provide enterprises with the opportunity of leapfrog development in terms of improving product production efficiency, saving labor cost and upgrading modern production level.

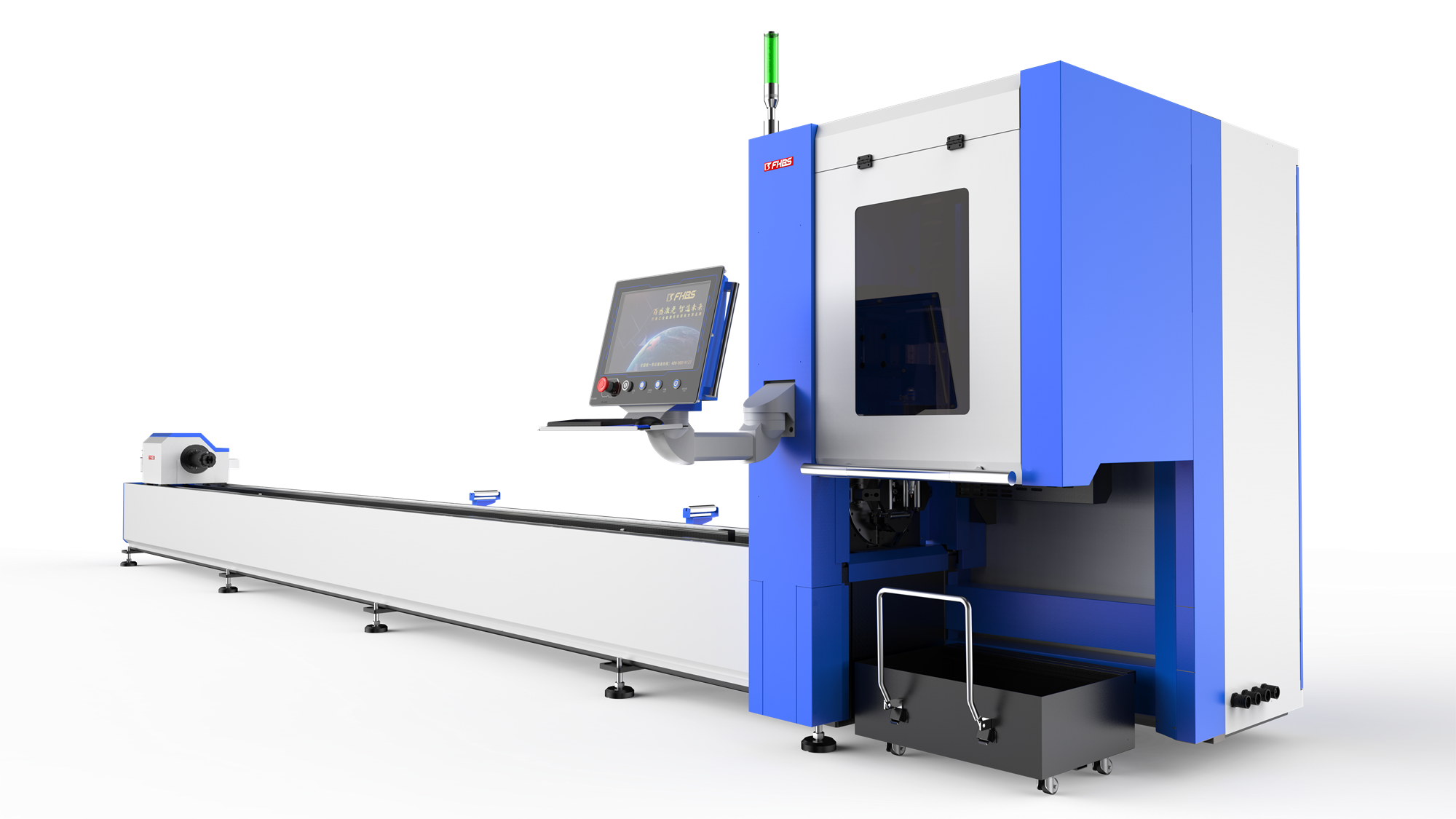

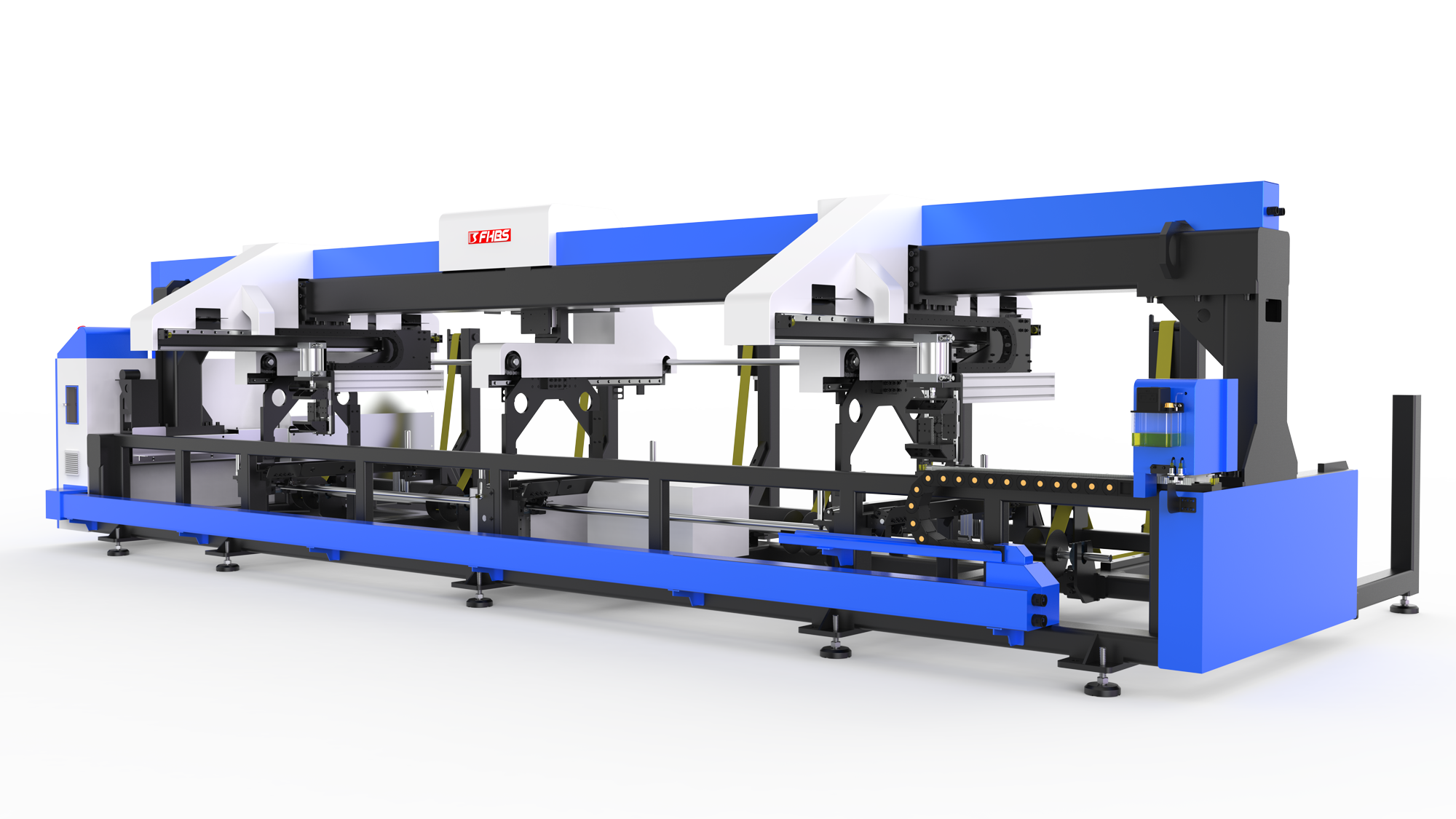

BAISHENG Laser automatic professional tube cutting technology is firmly in the vanguard of the industry. Our self-developed high-performance automatic loading and unloading system provides automatic and integrated pipe cutting solutions to enterprises.

It can automatically load round pipes, square pipes, rectangular pipes and other profiles, and is equipped with automatic pipe measurement functions and realize batch feeding without manual intervention. Besides, it can achieve a 40% increase in overall processing efficiency, saving labor and time costs.

The automatic unloading device can effectively prevent the workpiece from droop and swing, solving the problem of long workpiece cutting accuracy, and the following support doesn’t need manual hand holding.

A fully automatic professional tube laser cutting machine can achieve mass production by one person only

At present, the automatic loading and unloading system of tube laser cutting machine is in the stage of rapid development, and the stability and practicability of the equipment have been greatly improved.

Considering factors such as labor, time cost, product quality, etc., from the perspective of long-term development of the company and foreign development trends, building a laser cutting automated production line is an inevitable requirement for improving the competitiveness of the company and achieving efficient production.