Laser Cutting Machine Applied In Agricultural Machinery

At present, my country's agricultural machinery manufacturing industry is in a stage of rapid development, and new agricultural machinery and equipment are presenting the development trend of automation, specialization and diversification. With the continuous increase in market demand, as well as the continuous upgrading and emergence of new products, the agricultural machinery industry has put forward new demands for traditional manufacturing and processing methods.

The agricultural machinery processing parts are mostly sheet metal parts, and the most commonly used is punch processing, which requires a large amount of punch molds. The mold production process is complex, the manufacturing cycle is long, and the cost is high, which is not conducive to the development of new products; and the punch processing is suitable for mass production, and single-piece and small-batch production is subject to certain restrictions.

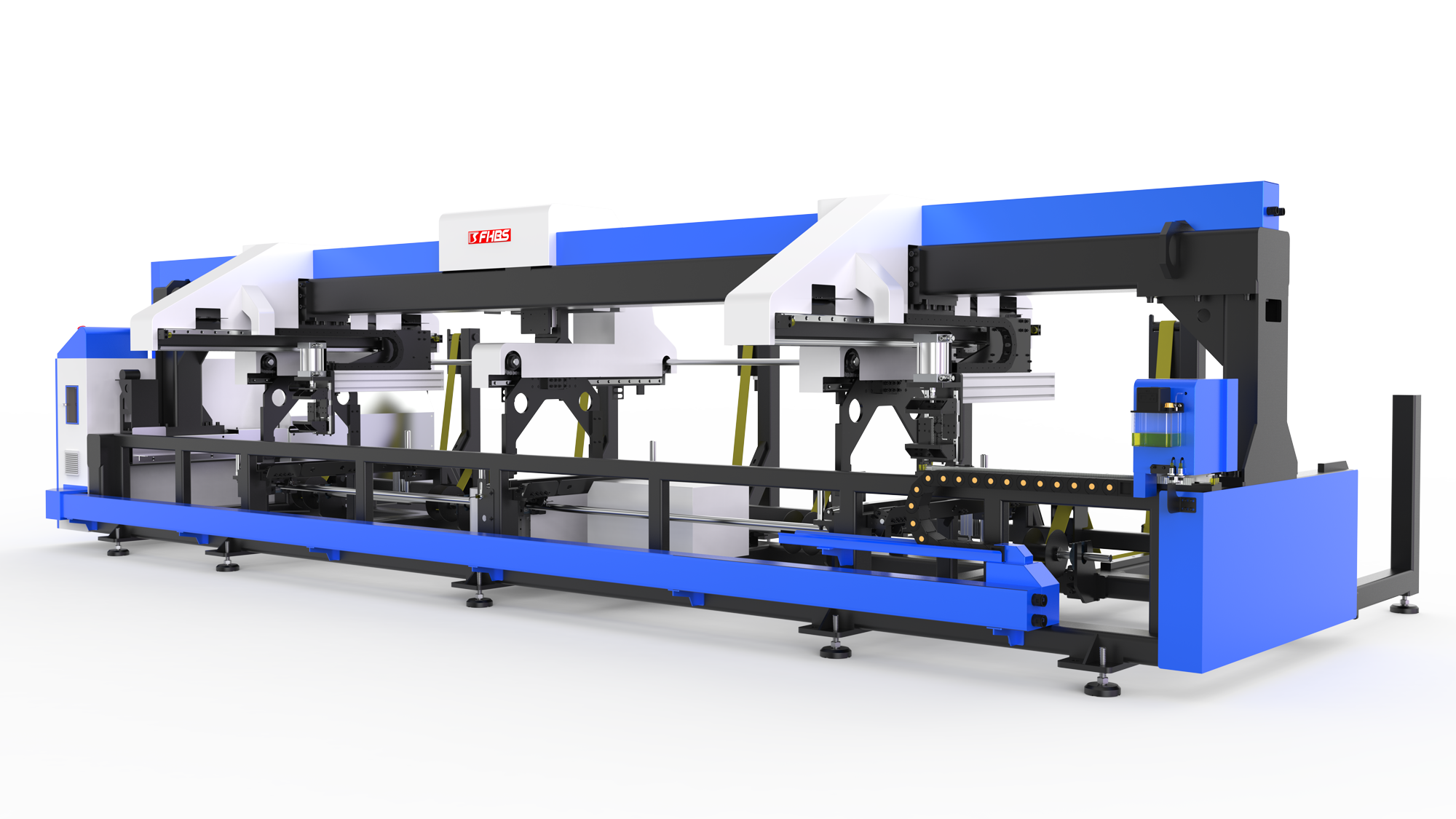

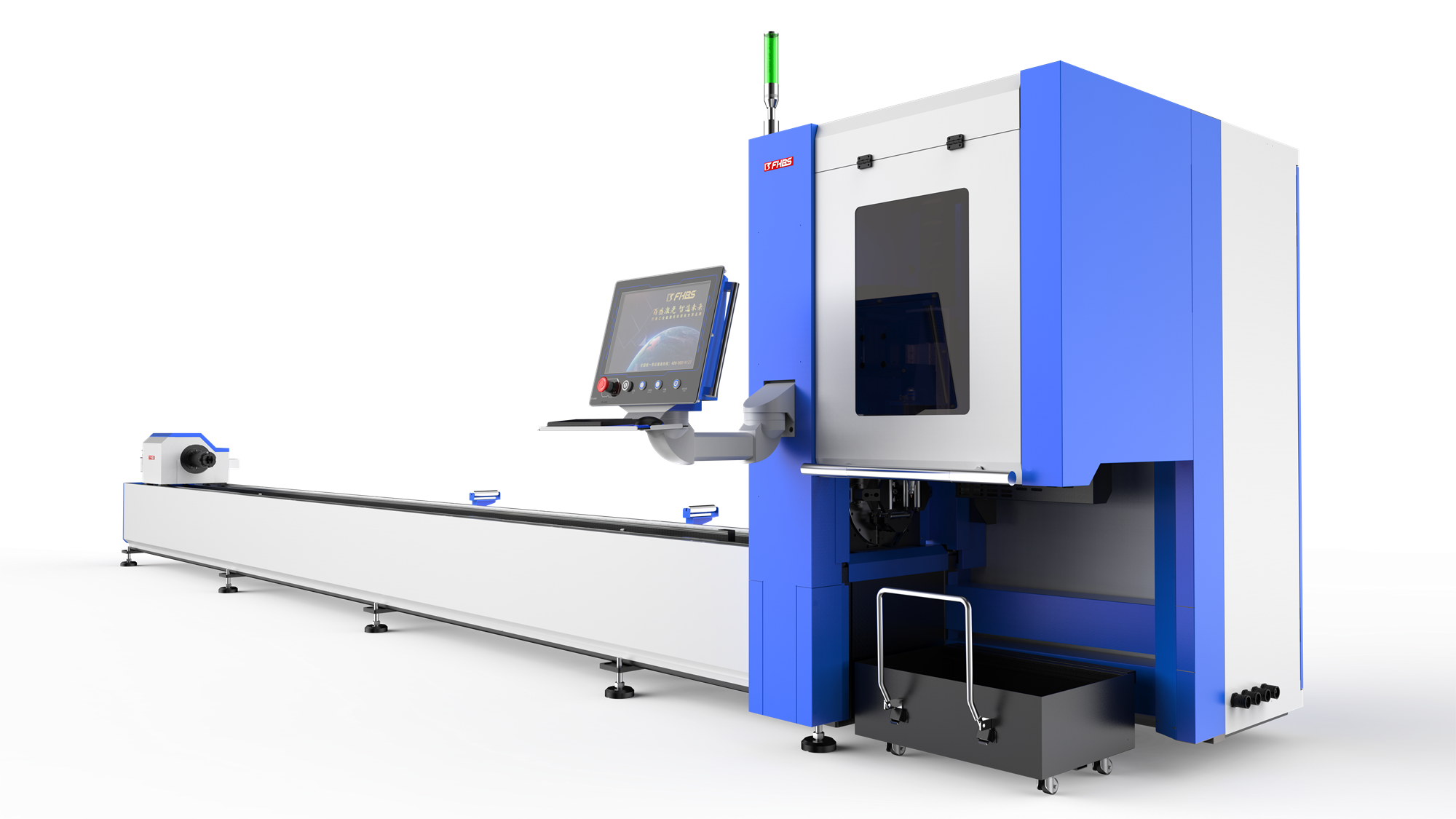

The mature application of laser cutting machine will provide new solutions for agricultural machinery manufacturing

High Accuracy

Traditional stamping processing requires positioning, and there may be positioning deviations that affect the accuracy of the workpiece. Laser cutting machine adopts advanced operation control system and can accurately position the cutting workpiece through professional laser cutting software. Non-contact processing, the cutting process does not damage the surface of the workpiece, the cutting gap is narrow (0.1mm~0.3mm), the heat effect on the position outside the processing point is small, and the sheet metal is not easy to deform.

No Graphics Restrictions

Laser cutting machine doesn’t need programming. It has a supporting special programming software, which can automatically generate the program and achieve any shape of plate/ tube cutting just only need to import CAD drawings. Large-format plates are processed and formed at one time, no need to consume molds, which is economical and time-saving.

New Product Development

Traditional punching machines will produce a large amount of leftover materials when processing complex circular, arc-shaped and special-shaped parts, which will increase the cost. The automated laser cutting machine can realize automatic typesetting and automatic nesting through cutting software, which fundamentally solves the problem of reusing scraps and plays a key role in reducing costs.

Material Saving

Traditional punching machines will produce a large amount of leftover materials when processing complex circular, arc-shaped and special-shaped parts, which will increase the cost. The automated laser cutting machine can realize automatic typesetting and automatic nesting through cutting software, which fundamentally solves the problem of reusing scraps and plays a key role in reducing costs.

Easy Operation

Punch processing has higher requirements for punch die design and mold making, while laser cutting machine only needs CAD drawing, the cutting control system is easy to learn and use, there is no experience requirement for the operator, and the later maintenance of the machine is simple, which can save a lot of labor and maintenance costs.

Safety & Environmental Protection

The stamping process has high noise and strong vibration, which is harmful to the health of the operators. Modern laser cutting machines use high-power-density laser beams to process materials, no noise, no vibration, and relatively safe. Equipped with dust removal and ventilation system, the emission meets national environmental protection requirements.