Laser Cutting Machine Applied In Cabinet Industry

The "new infrastructure" will promote the construction of 5G communication network infrastructure. Laser processing will penetrate every aspect of 5G base station construction and provide strong technical support for "new infrastructure".

It is expected to build at least 15,000 5G base stations in Hebei by 2020.

Shanghai: 10,000 5G base stations will be launched this year

Chongqing has announced plans to build 150,000 5G base stations by 2025

More than 50000 5G base stations will be built in Hubei this year

……

All provinces and cities have actively carried out 5G base station construction, and a large number of base station construction has stimulated the vitality of the downstream chassis and cabinet industry.

Common case cabinet is generally made of galvanized steel plate or stainless steel plate. And the base station cabinet is mostly made of aluminum alloy, which has the advantages of light weight, strong rigidity and good electromagnetic shielding effect. At present, it is widely used in the fields of electronics, communication network, power supply facilities and so on. In the construction of 5G base station, sheet metal case is an important part.

At present, in the environment of diversified customer demand and fierce market competition, chassis and cabinet manufacturers are facing the pressure of multi variety, customization, high quality, small batch, short delivery period and cost compression. In addition to seeking improvement and change in management, technological innovation is also one of the important solutions.

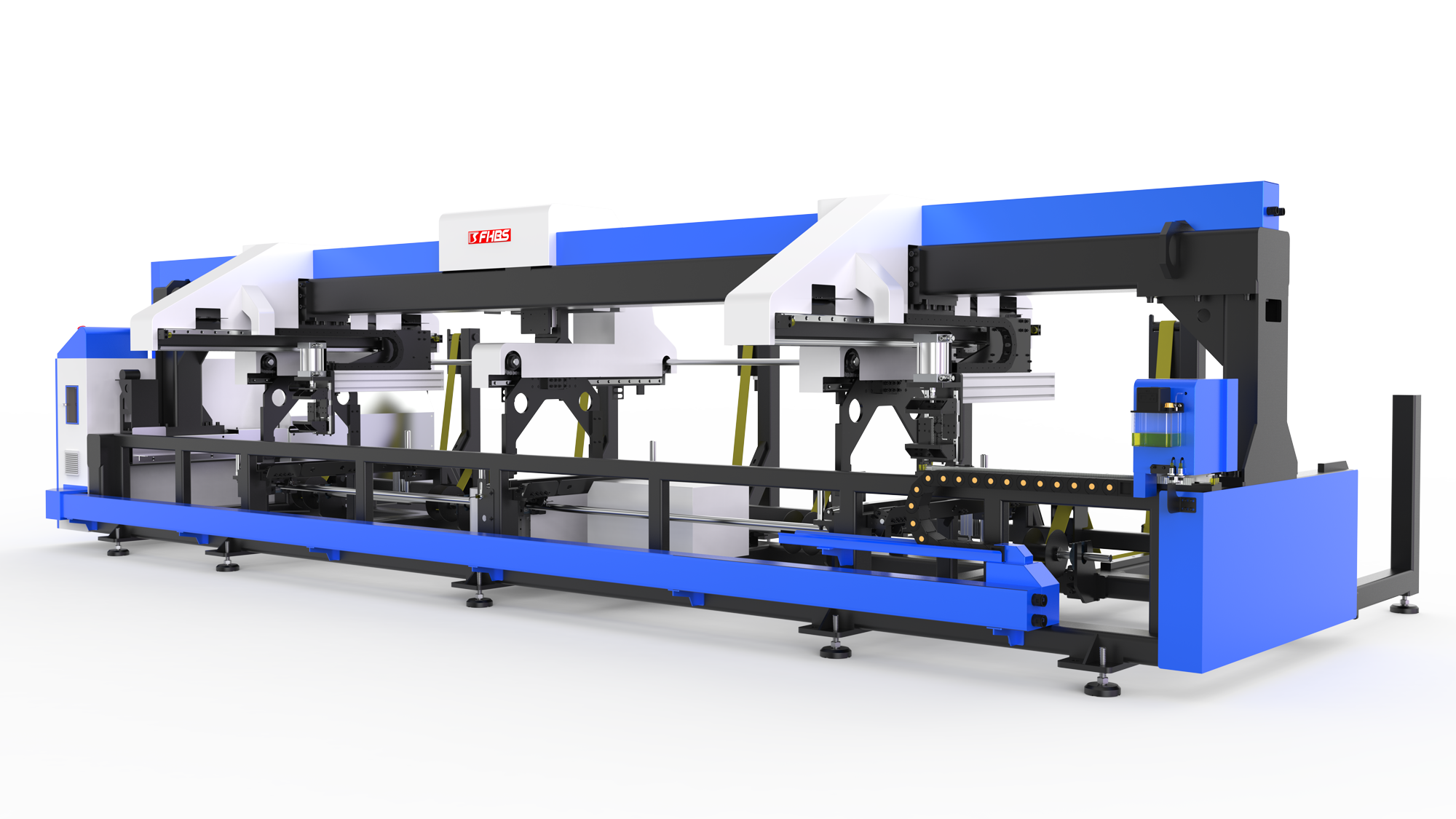

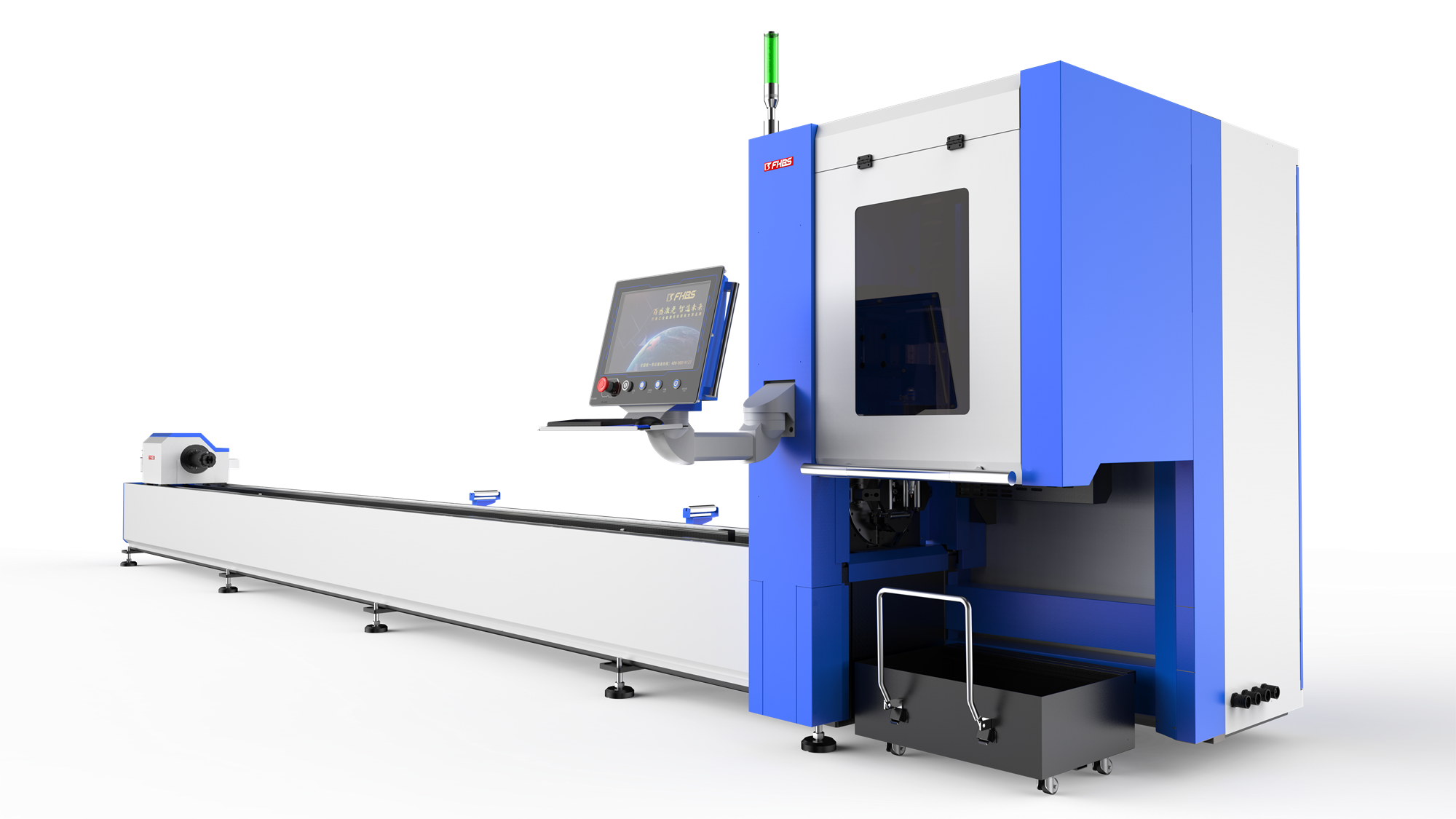

In the manufacturing process of chassis and cabinet, the traditional sheet metal process is cutting → punching → bending → welding and plasma / flame cutting → bending → welding. Cutting edge is easy to cause sharp edge, burr and burr on cutting edge, which affects the appearance of finished product, and the process is cumbersome and time-consuming.

Advantages Of Laser Cutting

1.No need to open mold, intelligent operating system can process arbitrary graphics, automatic typesetting, saving materials, sheet / pipe processing and molding at one time. Reduce mold design and manufacturing time, accelerate new product development progress.

2.No contact processing and the cutting process does not damage the surface of the workpiece. The slit is narrow (0.1mm~0.3mm), which has little influence on the heat outside the processing point, and the plate is not easy to be deformed

3.High cutting speed, high precision, smooth cutting, generally no need for subsequent processing. The qualified rate of workpiece is high, and it can be produced in batch automatically.

4.The equipment is easy to learn and operate, and there is no requirement for staff experience, and the later maintenance of the machine is simple, which reduces equipment maintenance costs.

The new infrastructure provides a great platform for the manufacturing industry, and the construction of 5G base station will bring opportunities to the cabinet industry from product to scale.