“Backstage Hero” of Metal Curtain Wall Industry

----- Laser Cutting Machine Applied In Metal Curtain Wall

As a kind of wall decoration applied in large buildings, the metal curtain wall is more and more favored by the construction industry with its good strength, flexible and changeable processing performance and safety. Among them, the aluminum curtain wall is the most widely used. It can effectively reduce the load of the building and provides a good choice for high-rise buildings by its good rigidity and high flatness.

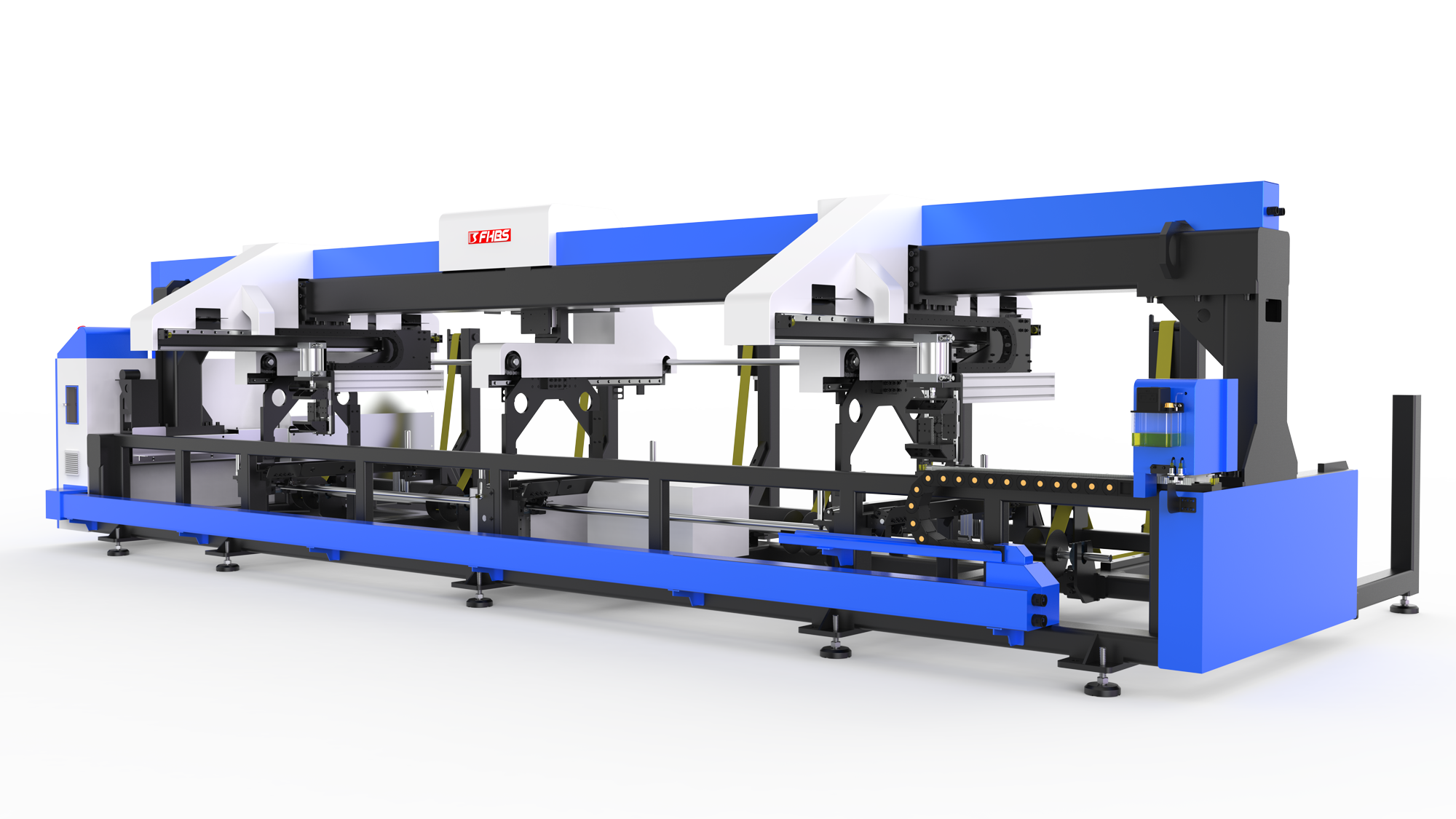

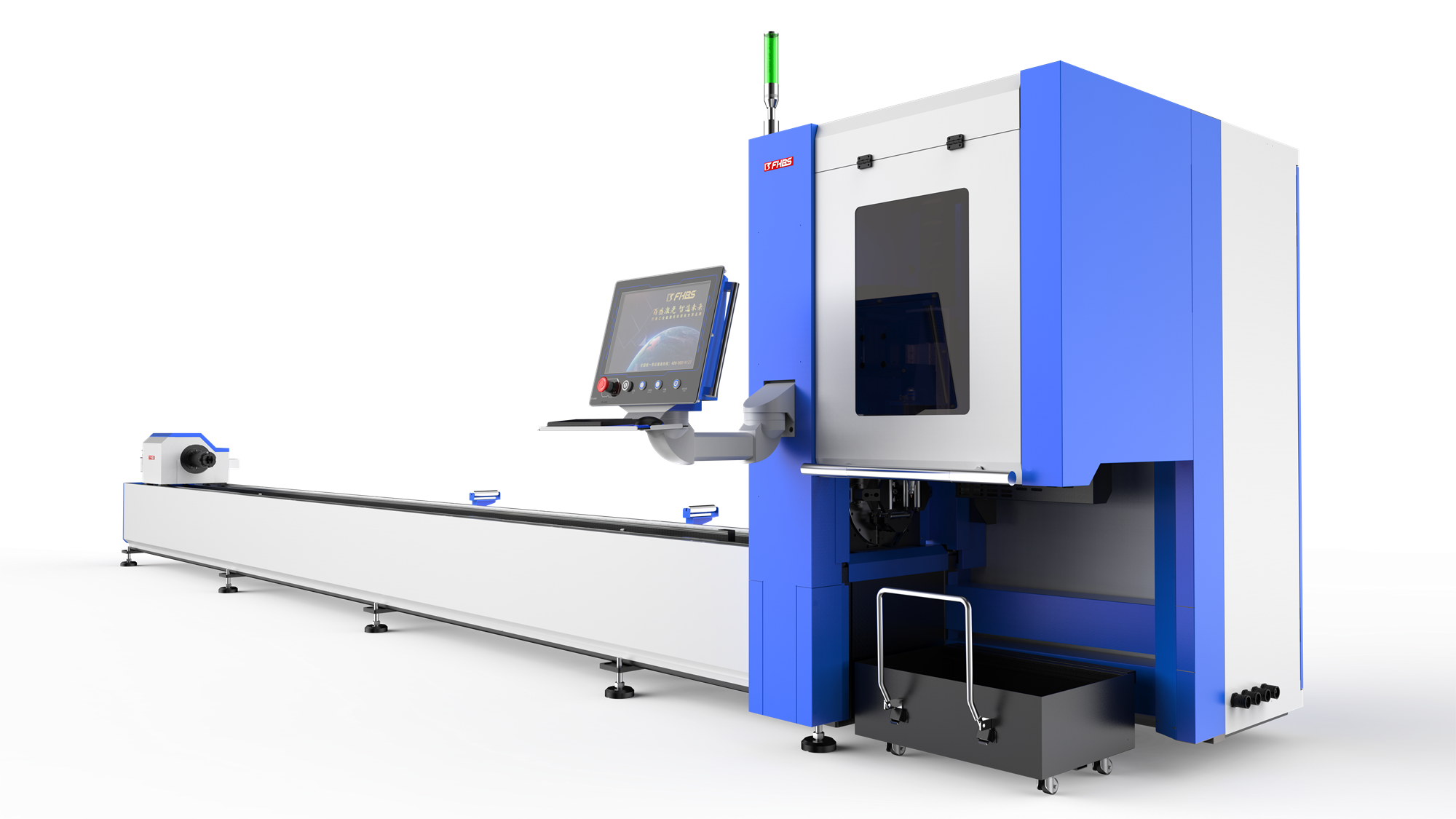

As the " Backstage Hero " of metal curtain walls, laser cutting machines provide more processing possibilities for aluminum curtain walls.

Commonly used aluminum plate cutting processes mainly include CNC shearing and water cutting. The shearing limit is large, there are burrs on the shearing surface, and cracks are prone to bend. Water cutting speed is slow. With the development of laser processing technology, fiber laser cutting machines have strongly joined the field of metal processing, with the characteristics of stably cutting a variety of metals, including high-reflectivity materials such as aluminum alloy and copper. At present, it has attracted much attention in the field of metal building materials processing.

With the rapid economic development in China, a large number of urban construction, airport, high-speed railway station and subway station projects have created a sharp increase in the demand for metal curtain walls. Many metal building materials processors are carrying out technological upgrading and expansion. In order to be in an advantageous position in the competition, shorten the manufacturing cycle and improve the product quality, high efficiency, high quality and automation are considered simultaneously in the technological transformation. Advantages Of Fiber Laser Cutting Machine Precision & Intelligence The laser cutting machine adopts a relative coordinate system, an intelligent cutting control system, and a large plate is processed and formed at one time, and the accuracy is greatly improved. Laser-cut round holes can accurately locate each bending centerline. Efficient Material Saving Laser cutting can meet the requirements of small and medium batch production without mold opening, which is conducive to the development of new products. Flexible processing, the production can be adjusted according to the situation at any time. Automatic typesetting, nesting and other processes to improve the utilization of plates. The processing items such as holes and slots are completed before bending, which greatly improves the production efficiency. The workpiece cutting surface is smooth and clean, high qualified rate because laser cutting makes cutting narrow and heat affected area is small when processing. It can effectively improve the product structure performance and appearance in the actual production. Low Maintenance Cost Laser cutting machine has high electro-optical conversion ratio, free maintenance of laser, stable performance, long service life and low equipment maintenance cost