With the advancement of science and technology and the improvement of people's health awareness, more and more manufacturers adopt their laser cutting equipment according to their actual situation.

There are many types of cars in the elevator industry, and with the improvement of people's aesthetic requirements, the interior decoration is also different, and the production cycle of new elevator products is getting shorter and shorter, resulting in the current situation of many types of elevator sheet metal parts and few single pieces.

The traditional processing method - multi-station CNC punching machine, due to the long mold opening cycle, complex programming, high requirements for operators, high workpiece defect rate, and high production cost, has been unable to keep up with the development trend of the elevator industry and is gradually being used by lasers. Cut instead.

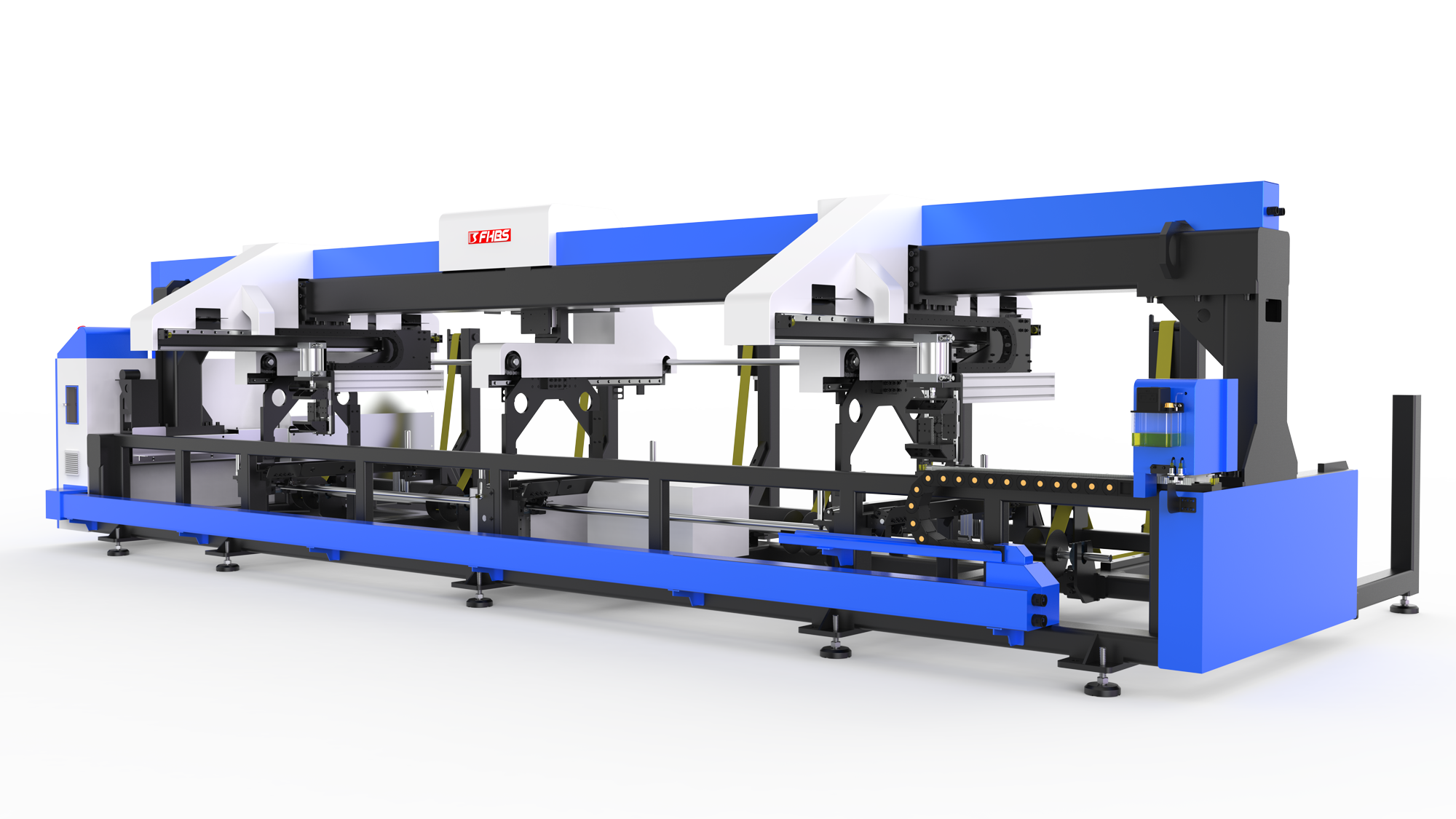

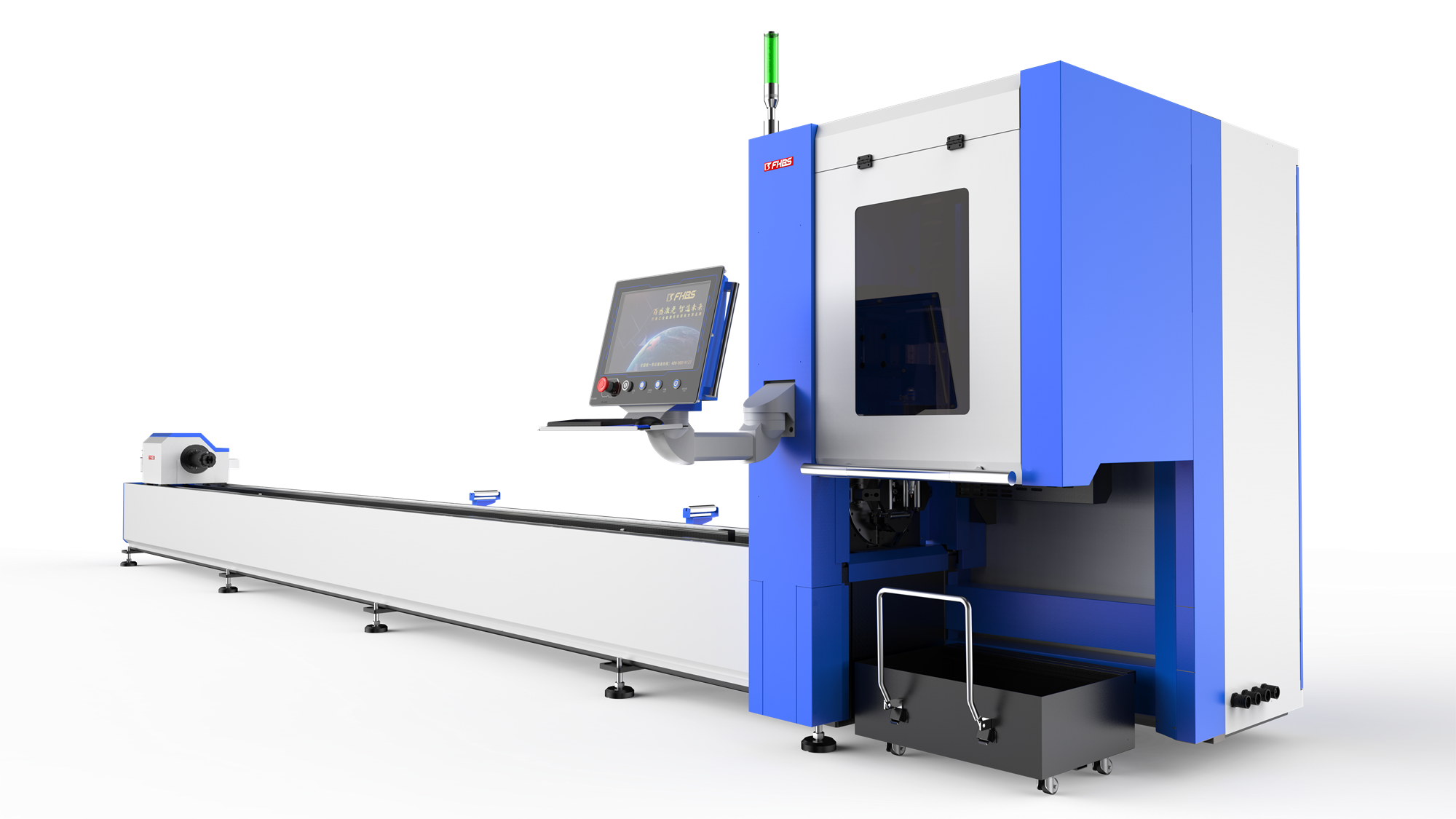

Huibaisheng's laser cutting technology can not only cut various metal sheets such as film materials and mirror materials, but also various complex lines and precision parts. It has good flexibility, low operating costs, and simple operation. One day It can be used, and the cutting speed is extremely fast, which greatly improves the production efficiency.